Jamesways, you could say, are the hardest working huts in snow business. Keeping a

camp of scientists (and an artist or two) relatively dry and warm throughout a season

on the Ice is a tall order, especially at the South Pole’s Summer Camp.

Summer Camp is the colony of Jamesways (partly pictured above) situated near the

Pole’s elevated station. Most of the huts are living quarters, and at least one serves

as a lounge. They’re put to a real test here because even at midsummer’s warmest,

outside temperatures average around −25 °C (−12 °F).

Jamesways are either centrally heated by oil burning heaters or use passive solar heat

and solar power for space heating. The key of course is heat retention, which is where

our heroes, the roof blankets, come in.

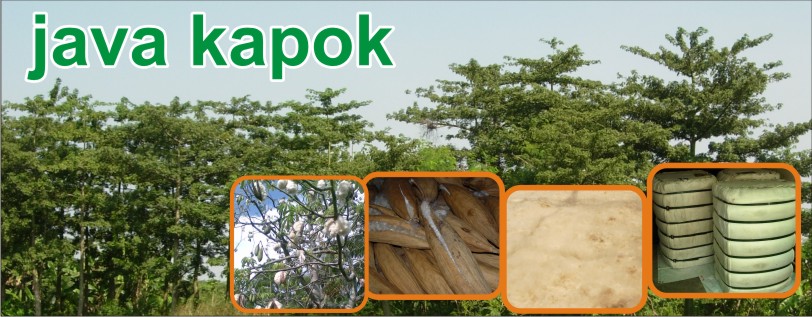

Roof blankets are a wall system typically using a layer of kapok fiber for insulation.

Kapok, derived from the ceiba tree’s seed pod, is ideal for its lightness, resiliency,

resistance to water and of course for its organic nature. Its flammability requires

flameproof encasement though, and these outer layers — typically muslin or

heavier cotton duck — are further treated with vinyl or plastic for extra durability

and weatherproofing.

Given all that, Jamesways still fall short on energy efficiency and tend to heat un-

evenly (the floor remains considerably colder than the rest of the space). Pushed

to its limit by the onset of Pole winter weather, Summer Camp shuts down for the

dark half of the year, to be dug out of snowdrifts and repopulated at sunrise the

following season. And so the cycle goes.

www.calacademy.org